WFD-430 Fully Automatic Roll Fed Paper Bags With Twisted Handle Machine

This is special machine for the production of shopping bags (block bottom bags) with twisted rope handle made of paper. The material can be paper roll or printed paper roll. Whole machine is controlled by computer central control system with touch screen and servo motor for cut-off length control.

If you want to produce paper bags in medium sizes, WFD-430 is the ideal equipment for you. This model can be adjusted between 220 mm-450 mm bag width and 80 mm-220 mm bottom width.

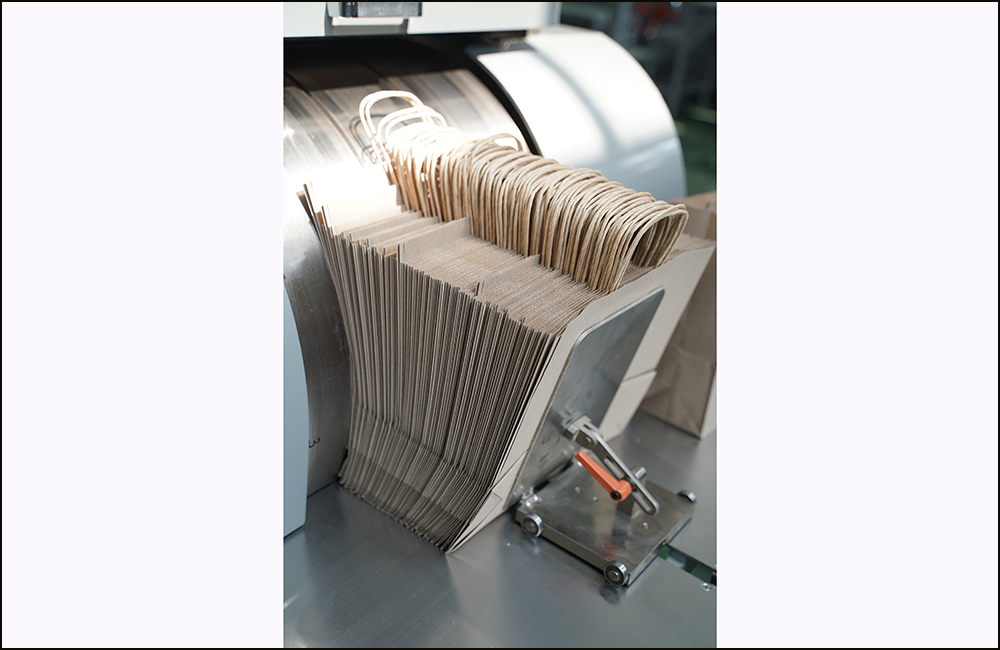

With its advanced technology, the machine automatic paper fed from roll, tube forming, cut-off, bottom forming, bottom glue, bag forming and final bag output. All of these steps are fully automated, eliminating the need for manual operation and maximizing productivity.

Choosing this machine to revolutionize your paper bag manufacturing process and stay ahead of the competition. With its exceptional features and professional performance, it can meet the various needs of professional packaging.

|

Machine Model |

WFD-430 |

|

Paper Roll Width |

630-1330mm |

|

Paper Bag Width |

220-450 mm |

|

(if without handle) |

(160-450 mm) |

|

Paper Tube Length |

270-560mm |

|

(if without handle) |

(270-600 mm) |

|

Bag Bottom Width |

80-200 mm |

|

Paper Thickness |

80-150gsm |

|

(if without handle) |

(70-150 gsm) |

|

Max. Roll material diameter |

¢1200 mm |

|

Material Core Diameter |

¢76mm(3″) |

|

Length of twisted rope (customizable) |

300-400 mm |

|

Diameter of Twisted Rope |

4-6 mm |

|

Handle Patch Length |

190 mm |

|

Handle Patch Width |

35-50 mm |

|

Handle patch Roll Diameter |

¢1000 mm |

|

Paper Patch Roll Width |

70-100 mm |

|

Paper GSM for Handle patch |

110-250gsm |

|

Speed |

70-130Bags/min. |

|

Total Power |

33KW |

|

Machine Weight |

19000KG |

|

Machine Dimension (L*W*H) |

|