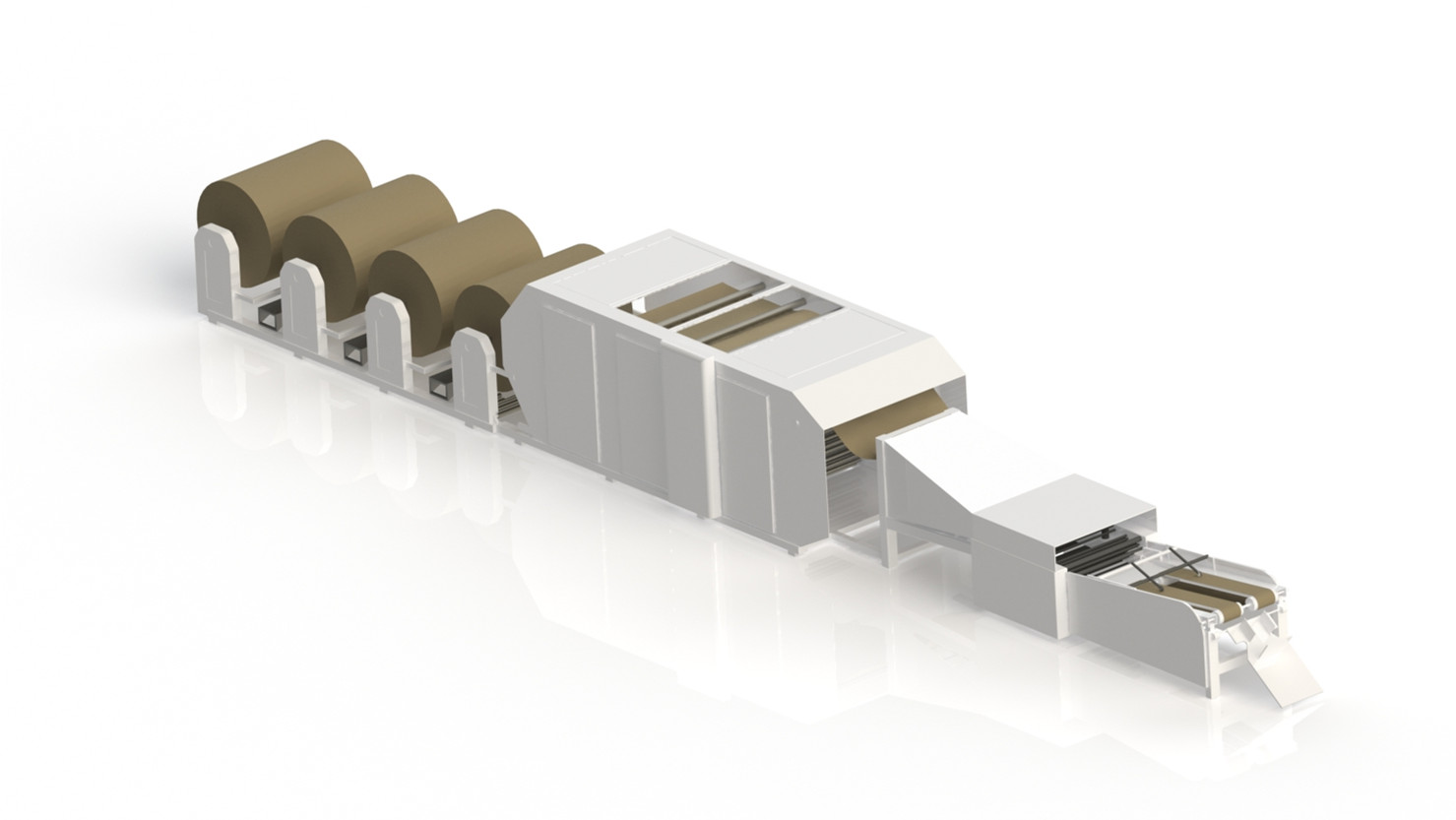

WFD-750/750A Multi Layer Paper Sack Bag Tuber Machine

Properties and uses:

PAPER VALVE SACKS CEMENT BAG PRODUCTION LINE designed to meet the needs of our customers, highly efficient and technologically advanced Paper Cement bag production line. By maximizing production efficiency and minimizing waste, our Multi layers valve Industrial bag making machine mainly applicable for 1 to 4 layers Industrial kraft paper bags for cement, ceramic tile adhesive bag, chemical products packaging, milk powder and flour packaging,etc. This production line offers a cost-effective solution for heavy duty sack kraft paper bag manufacturers. By implementing steps including tube forming via tuber machine with inline printing, valve bottom bag opening, folding, gluing, compacting and finally form a complete valve bag, even inner or outside paper reinforcement within a fully automatic process, this machine can effectively save labor costs. Most stable valve forming process and special bag counting function and bag collection system greatly improve sack kraft bags efficiency. Thanks to perfect technologies and fast production speed, this machine can produce various multi-layers sack kraft paper bags with high quality. Our machine is built to withstand continuous use, ensuring long-lasting performance and minimal maintenance requirements. with over 25 years paper bag machine manufacturing experience, Our dedicated team of experts offers comprehensive support, from installation and training to continuous technical assistance and prompt spare parts availability. The machine has optional of inline 2-4 colors inline printing, upto 4 layers paper and 1PE for all types of multi-layers sack kraft paper bags.

|

Machine Model |

WFD-750/750A |

|

Tube Length |

500-1100 mm (can be customized) |

|

Tube Width |

300-600 mm (can be customized) |

|

Paper Thickness GSM |

70-140 g |

|

Paper Roll Width |

620-1250 mm |

|

Speed (According to cutting length) |

60-130 pcs/min |

|

Layers |

2-5 layers |

|

Total machine dimension (L*W*H) |

26000 mm*3050 mm*2680 mm |

|

Total weight |

22 T |

|

Total power |

45 kw |